Prototype PCB manufacturers play a crucial role in the rapidly advancing tech industry, providing the foundation for innovation and development in electronic devices. As technology continues to evolve at a rapid pace, the demand for high-quality and reliable prototype PCBs has never been greater. In this article, we will explore the significance of prototype PCB manufacturing in the tech sector, delve into the key considerations when selecting a manufacturer, and examine the impact of technological advancements on PCB prototyping. By understanding the role of prototype PCB manufacturers, we can gain insights into how they drive innovation, address challenges, and capitalize on opportunities in the dynamic landscape of the tech industry.

Introduction to Prototype PCB Manufacturing in the Tech Industry

Overview of Prototype PCBs

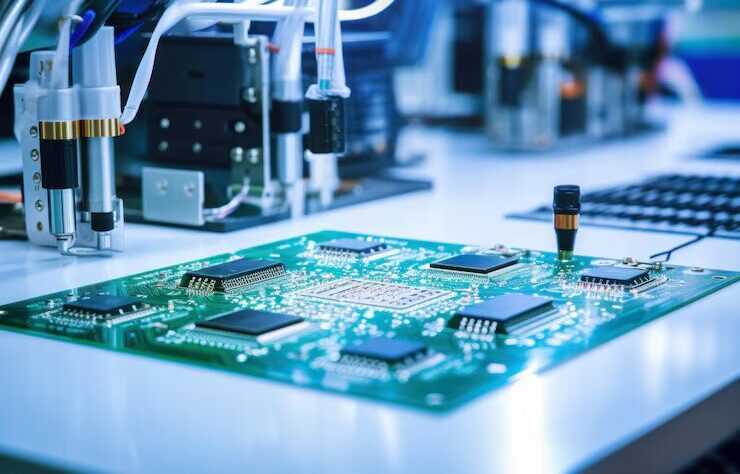

Prototype PCBs, or printed circuit boards, play a crucial role in the development of electronic devices by providing a platform for testing and refining designs before full-scale production. They serve as the foundation for assembling components and creating functional prototypes.

Significance of Prototype PCBs in Tech Development

Prototype PCBs enable tech companies to iterate quickly, reduce time-to-market, and minimize costly errors during the design phase. By allowing for rapid testing and modifications, they facilitate innovation and help bring cutting-edge technologies to life.

Key Considerations in Selecting a Prototype PCB Manufacturer

Factors to Evaluate in Choosing a Manufacturer

When selecting a prototype PCB manufacturer, factors such as expertise, capabilities, production capacity, lead times, and cost-effectiveness should be carefully considered. It’s essential to partner with a manufacturer who can meet your specific requirements and deliver quality products consistently.

Importance of Quality and Reliability

Quality and reliability are paramount when it comes to prototype PCB manufacturing. Choosing a manufacturer with a track record of producing high-quality boards that meet industry standards is crucial to ensure the success of your projects and the long-term performance of your products.

The Impact of Rapid Technological Advancements on PCB Prototyping

Adapting to Evolving Technologies

With the tech industry evolving at breakneck speed, prototype PCB manufacturers must stay abreast of the latest advancements in materials, components, and manufacturing processes to meet the demands of cutting-edge technologies. Flexibility and adaptability are key in responding to industry trends and customer needs.

Accelerating Prototyping Processes

Rapid technological advancements have fueled the need for faster prototyping processes. Prototype PCB manufacturers are increasingly leveraging automation, digital tools, and streamlined workflows to expedite production and deliver prototypes in a timely manner. This accelerated pace is essential in keeping up with the fast-paced tech landscape.

Quality Assurance and Testing Processes in Prototype PCB Manufacturing

Ensuring PCB Reliability and Performance

Quality assurance and testing are critical stages in prototype PCB manufacturing to ensure the reliability and performance of the boards. Rigorous testing processes, including functional tests, electrical tests, and reliability assessments, help identify and rectify any anomalies before mass production, guaranteeing a high-quality end product.

Testing Protocols and Standards

Prototype PCB manufacturers adhere to industry standards and protocols to validate the functionality and quality of their boards. Compliance with standards such as IPC-A-600 for acceptability of printed boards ensures that the prototypes meet the necessary criteria for performance and reliability, offering customers peace of mind and confidence in their products.

Customization and Flexibility in Prototype PCB Design

Meeting Unique Design Requirements

When it comes to prototype PCB design, one size definitely does not fit all. Prototype PCB manufacturers like PCB-togo Electronic, Inc. understand the importance of meeting unique design requirements for their clients. Whether it’s a specific form factor, special material needs, or unique circuit configurations, customization is key to ensuring the prototype PCB meets the exact specifications of the project.

Options for Customization and Iteration

The beauty of working with a prototype PCB manufacturer is the flexibility they offer in terms of customization and iteration. Clients have the freedom to experiment with different designs, make changes on the fly, and iterate quickly to refine their prototypes. This level of flexibility not only speeds up the development process but also ensures that the final product is tailored to meet the client’s specific needs.

Role of Prototype PCB Manufacturers in Innovation and Product Development

Collaboration with Tech Companies for Innovation

Prototype PCB manufacturers play a crucial role in fostering innovation and product development in the tech industry. By collaborating closely with tech companies, they help bring cutting-edge ideas to life by providing the necessary expertise and resources to turn concepts into tangible prototypes. This collaboration is essential for pushing the boundaries of what is possible in technology.

Enabling Quick Iteration and Development Cycles

One of the key contributions of prototype PCB manufacturers is their ability to enable quick iteration and development cycles. By offering rapid prototyping services, they allow tech companies to test out ideas, gather feedback, and make necessary adjustments in a timely manner. This rapid iteration process is instrumental in speeding up product development and bringing innovations to market faster.

Addressing Challenges and Opportunities in the Rapidly Advancing Tech Industry

Challenges Faced by Prototype PCB Manufacturers

In the rapidly advancing tech industry, prototype PCB manufacturers face challenges such as keeping up with evolving technology trends, meeting tight deadlines, and ensuring quality control. Staying ahead of the curve requires constant innovation and adaptation to new technologies and methodologies.

Opportunities for Growth and Expansion

Despite the challenges, there are ample opportunities for growth and expansion in the prototype PCB manufacturing sector. As the demand for customized, high-quality PCBs continues to rise, manufacturers have the chance to expand their capabilities, explore new markets, and forge strategic partnerships to capitalize on the growing tech industry.

Future Trends and Growth Prospects for Prototype PCB Manufacturers

Technological Advancements Shaping the Industry

The future of prototype PCB manufacturing is being shaped by technological advancements such as the rise of Internet of Things (IoT), artificial intelligence, and advanced manufacturing processes like 3D printing. Manufacturers that embrace these technologies and adapt to the changing landscape will be well-positioned for growth and success in the coming years.

Potential Market Trends and Emerging Opportunities

As the tech industry continues to evolve, prototype PCB manufacturers can expect to see new market trends and emerging opportunities. From the increasing demand for eco-friendly and sustainable PCB materials to the rise of niche markets like wearable technology and autonomous vehicles, there are plenty of avenues for manufacturers to explore and capitalize on in the future.

In conclusion, prototype PCB manufacturers like PCB-togo Electronic, Inc. play a vital role in shaping the future of technology through their dedication to quality, customization, and innovation. As the tech industry continues to advance, the collaboration between tech companies and prototype PCB manufacturers will be essential in driving progress and meeting the evolving needs of consumers. With a focus on quality assurance, flexibility in design, and a proactive approach to technological advancements, prototype PCB manufacturers are well-positioned to lead the way in the ever-changing landscape of the tech industry.

FAQ

Why are prototype PCBs important in the tech industry?

Prototype PCBs serve as the foundation for the development and testing of electronic devices, allowing for quick iterations, customization, and ensuring the reliability and performance of the final product.

What factors should be considered when selecting a prototype PCB manufacturer?

When choosing a prototype PCB manufacturer, factors such as quality, reliability, customization options, testing processes, and adherence to industry standards should be carefully evaluated to ensure the desired outcomes for your project.

How do prototype PCB manufacturers contribute to innovation in the tech industry?

Prototype PCB manufacturers collaborate with tech companies to drive innovation by providing quick iteration cycles, enabling customization, and staying abreast of technological advancements to meet the evolving demands of the industry.

What are some future trends and growth prospects for prototype PCB manufacturers?

Future trends for prototype PCB manufacturers include advancements in technology shaping the industry, potential market trends, and emerging opportunities for growth and expansion within the rapidly evolving tech sector.

Original Sources: https://writeupcafe.com/the-role-of-a-prototype-pcb-manufacturer-in-the-rapidly-advancing-tech-industry/